SES AI has developed the world’s most advanced Li-Metal battery technology for EVs and eVTOLs. We have combined the high energy density of Li-Metal with the large-scale manufacturability of conventional Lithium-ion batteries, helping promote the transition from the global dependence on fossil fuel-based automotive vehicles to clean and efficient EVs and eVTOLs.

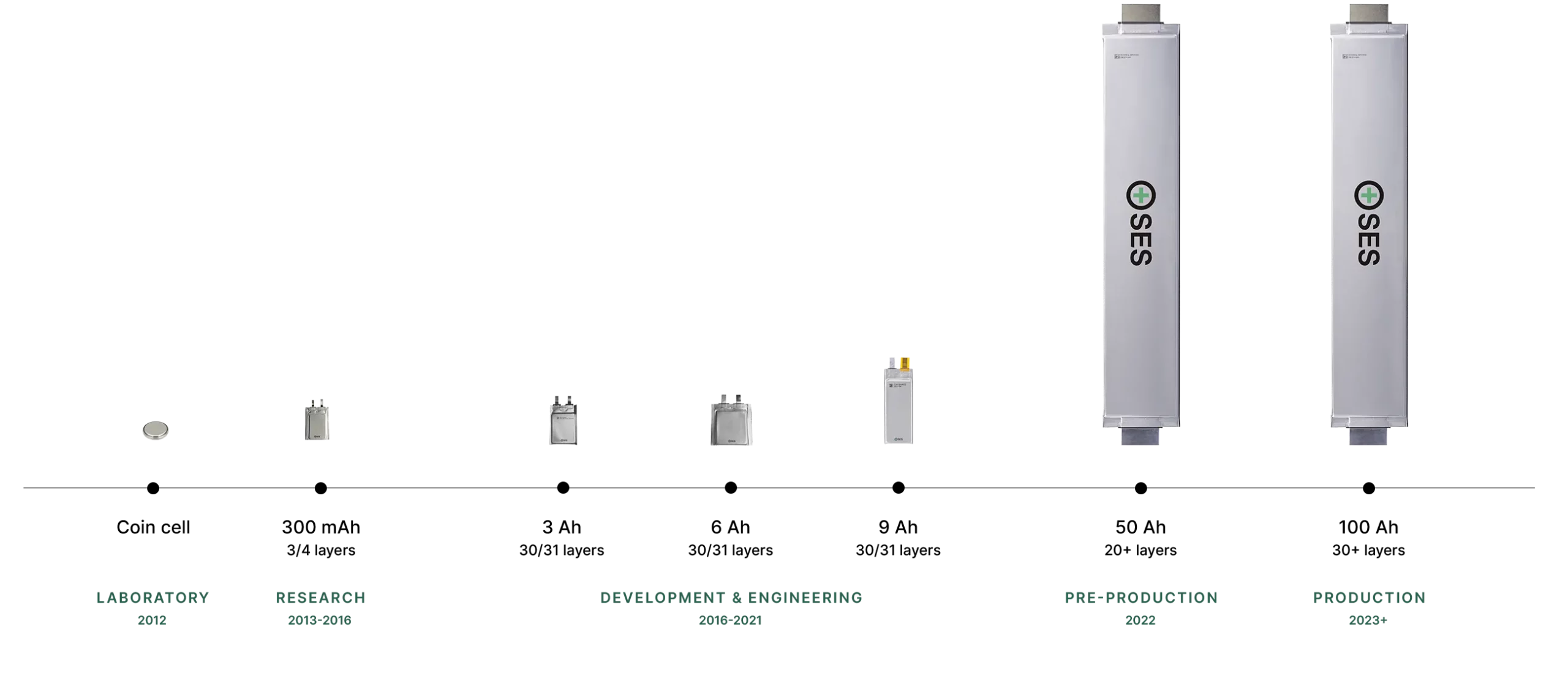

The road to commercialization of battery breakthroughs is long and winding, often taking more than 10 years to go from research and development to start of production.

A-sample batteries are functional prototypes developed for OEMs based on their technical specifications.

B-sample batteries are A-sample batteries manufactured under much higher throughput

and with its cell chemistry and design finalized.

C-sample batteries are fully functional, mature samples for mass production and tested for full drivability in actual vehicles.

CHANG HWAN KIM

VP Energy & Environmental Chemical Systems, Hyundai