July 22, 2022 In honor of John B. Goodenough’s 100th birthday: What America can learn from China’s success in EV batteries

China’s EV battery strategy can be divided into three phases

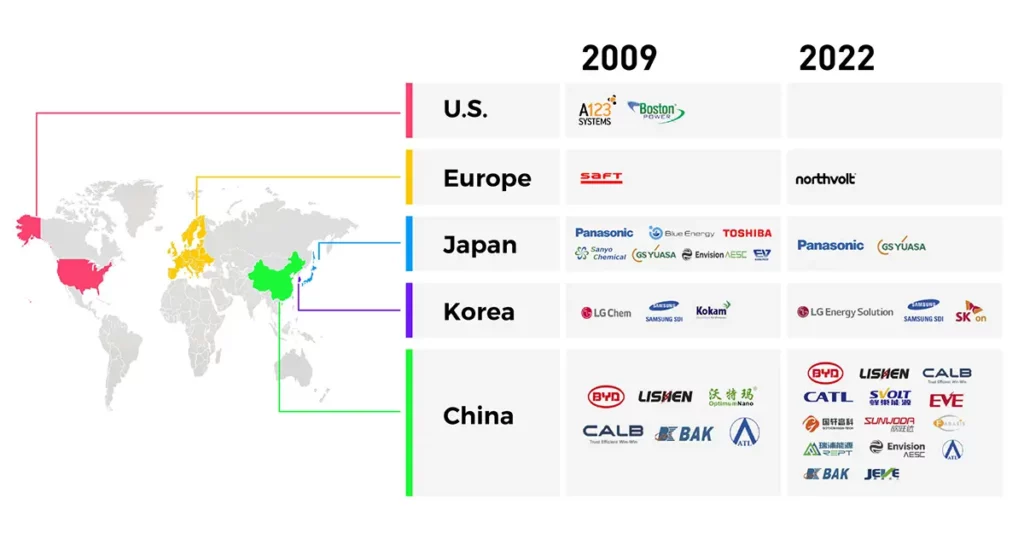

Phase I (2009-2015): Incubate with subsidy

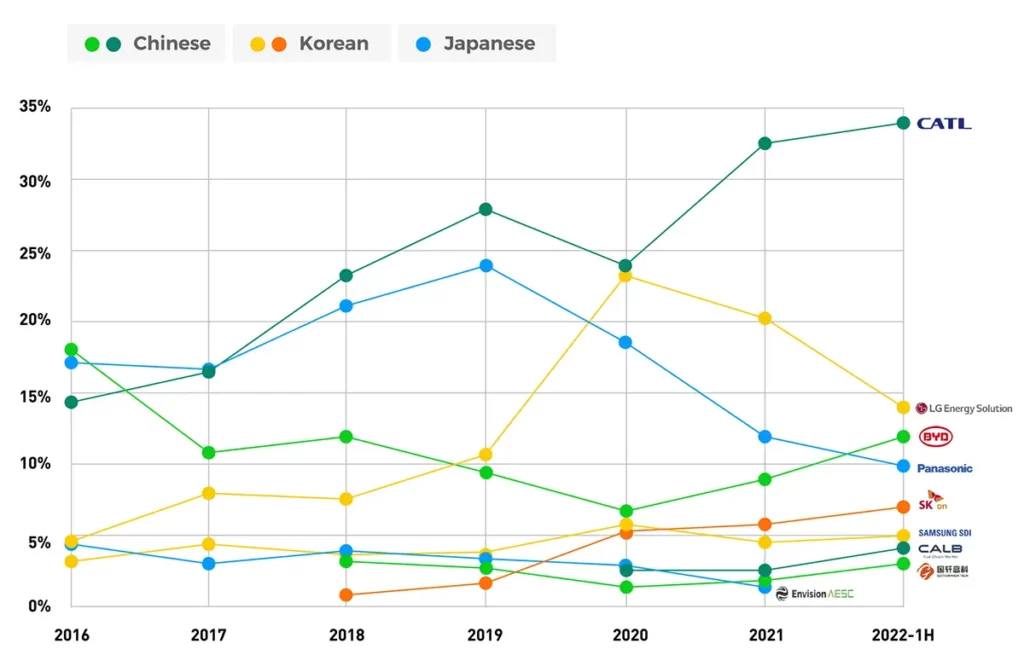

In January 2009, to support China’s nascent EV battery industry, Chinese Ministry of Science and Technology published the first subsidy program granting 50,000 rmb for each hybrid vehicle and 60,000 rmb for each pure battery vehicle. This unleashed a mayhem, more than 1,500 battery companies were established, many battery company stocks skyrocketed, the industry was filled with empty promises, not that different from the bubble in American EV SPAC companies in 2020. Despite government subsidy, the Chinese EV battery suppliers could not compete with the Korean and Japanese suppliers. In 2011, the China-based Japanese battery supplier ATL spun-off its EV battery business and formed CATL, but it was no match to the Korean, even by 2015 CATL’s revenue was only a small fraction of that of Samsung SDI.

In the same period, the American EV battery company A123 went public in 2009, it would later receive $249m grant from the US Department of Energy but lose the competition to LG Chem and eventually go bankrupt in 2012 and get bought by the Chinese.

During this period, both Chinese and American governments supported their own EV battery companies, but neither could compete with the more advanced Korean and Japanese suppliers with better technology and capability. Both Chinese and American markets were dominated by the Korean and Japanese suppliers, the American companies went bankrupt while the Chinese companies hung in there, and things were about to change.

Phase II (2015-2019): Grow under protection

China’s number 1 motivation to transition from internal combustion engine to EV is national security since about 70% its oil supply is imported through shipping routes controlled by the US Navy, hence China was not going to let foreign companies dominate its new EV industry. From 2015 to 2016, the Chinese Ministry of Industry and Information Technology published 4 “White Lists”, that required OEMs to buy batteries from suppliers on the 4 “White Lists” if they wanted to qualify for government subsidy. There were also technical barriers to entry such as minimum manufacturing plant capacity, cell energy density, vehicle range per charge, etc. that helped improve the quality. But the most controversial and effective measure was that no Korean or Japanese suppliers were on the 4 “White Lists”.

In the same period, the Korean EV battery suppliers were plagued with their own issues including the Samsung Galaxy Note 7 battery explosion, and the IP fight between LG Chem and SK Innovation. Korean market share in China dropped from more than 60% in 2015 to almost negligible today.

This window allowed Chinese EV battery suppliers to quickly consolidate, catch up with the Korean and Japanese in technology and manufacturing capacity, and leapfrog them in mine-to-men EV battery supply chain including the world’s most comprehensive list of lithium and nickel mine assets and AI battery health monitoring software used for battery leasing and swapping.

Phase III (2019-now): Compete and win in the open

In June 2019, the Chinese government officially terminated the controversial “White Lists” and not only welcomed the Korean and Japanese EV battery suppliers back to China, it even broke its previous joint venture requirement and invited the world’s leader in EV technology Tesla to build Shanghai Giga and become the first 100% foreign wholly owned automotive company in China.

At this point, the Chinese EV battery suppliers were strong enough to compete head-to-head with the foreign suppliers, continuing the protectionist “White Lists” would make them complacent and less competitive globally, inviting foreign competition back would make them stronger. Now Chinese EV battery suppliers CATL, BYD, Gotion, SVOLT, and EV makers Nio, XPeng and Li Auto are not only thriving in China but also expanding in Europe and other major markets.

Summary

Imagine A123 didn’t go bankrupt in 2012, and the US Department of Energy issued protectionist measures similar to China’s “White Lists” after giving it $249m grant, maybe A123 would become today’s CATL and we would see a few American companies in the world’s top EV battery suppliers list.

If we want to build an American EV battery supply chain dominated by foreign companies then we don’t need to change, the Korean, Japanese and Chinese will come since America has a large market. But if we want to build an American EV battery supply chain dominated by American born and bred companies, then we should reconsider our strategy. It’s nothing new, many countries used it before in other industries, including ourselves.

Share this post

Author

-

Dr. Qichao Hu is the founder and CEO of SES AI (NYSE: SES), the Boston-based company pioneering the world’s lightest long-range Li-Metal battery and transparent EV battery supply chain. Dr. Hu has a BS in Physics from MIT and a PhD in Applied Physics from Harvard.

View all posts